The EX series counter-flow enthalpy recovery exchanger offers an alternative to the classic counter-flow heat exchanger in buildings that suffer from low air humidity.

- The new generation of enthalpic counterflow heat exchangers EX-P 03 offers an alternative to standard heat exchanger models. In the case of operation in residential areas with low indoor humidity, these heat exchangers maintain a pleasant indoor climate by recovering moisture from the exhaust air.

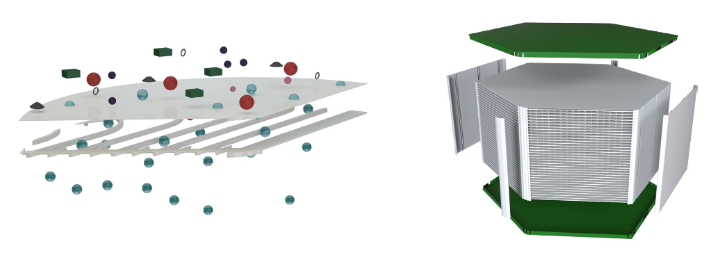

- This process is made possible by a unique polymer membrane with a microporous structure that allows water vapor molecules to pass through, but blocks bacteria, germs, mold, gases, and odors. This design allows high hygiene standards to be maintained even in sanitary areas, kitchens, and laboratories, and other areas with constant sources of air pollution.

- The supply and exhaust air flows move in opposite directions in the air channels of the heat exchanger plates. Sensible and latent heat energy is transferred by means of the heat exchanger membrane.

- A comparison of a standard plate heat exchanger (RSX-P 03 series) and an enthalpic heat exchanger (EX-P 03 series) shows that standard heat exchangers have a higher sensible heat recovery efficiency compared to enthalpic heat exchangers, but the EX-P 03 series enthalpic heat exchangers have a higher overall heat recovery efficiency due to the recovery of latent heat from water vapor.

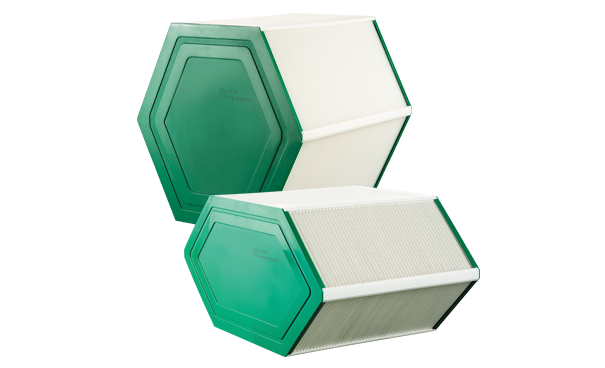

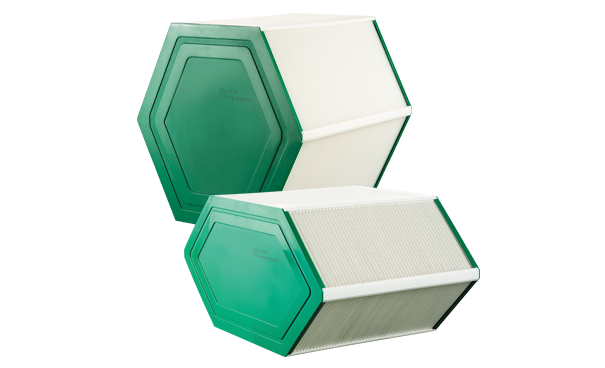

DESIGN

- The enthalpy heat exchanger EX-P 03 has the same shape as the standard exchanger RSX-P 03, so there is no problem with its replacement.

- The geometry of the slats is developed to maximize the efficiency of heat and moisture transfer

- The exchanger casing is extra rigid, which guarantees a long service life

MATERIALS USED

- The exchanger fins are made of a microporous polymer membrane with an antibacterial coating

- HPS is a high-strength hardened polystyrene with high stability and durability. It is from this that the casing is made.

- A high-quality synthetic-based hot-melt polymer adhesive used in the food and pharmaceutical industries is used to seal and connect the slats and the casing.

OPERATING AND STORAGE CONDITIONS

- The materials used allow the operation, storage and transportation of heat exchangers in temperature conditions from -25 to +50 ° C.

- Storing heat exchangers in direct sunlight is prohibited.

- EX-P 03 enthalpy heat exchangers do not freeze in winter under normal operating conditions.

HEAT EXCHANGER MAINTENANCE

- The exchanger cannot be operated without filters installed on both air inlets.

- Filters should be checked regularly and replaced if necessary.

- Clean the exchanger by rinsing it with warm water up to 30 °C.

- Do not use high-pressure water jets or compressed air to clean the exchanger, as this could damage it.rattan membranes.

Heat exchanger parameters at: 250m3/h. indoor/outdoor air ratio 1:1, outdoor air temperature 7°C and relative humidity 75%, indoor air temperature 20°C and relative humidity 37%, results from calculation software

|

FEED |

REMOVAL |

| Standard air quantity INLET |

250 m3/h. |

250 m3/h. |

| Temperature INLET |

7°C |

20°C |

| Relative humidity INPUT |

75% |

37% |

| Absolute humidity INPUT |

4.64g/kg |

5.36g/kg |

| Enthalpy INPUT |

18.75 kJ/kg |

33.81 kJ/kg |

| Air volume OUTPUT |

247.24 m3/h. |

247.76 m3/h. |

| OUTPUT temperature |

16.78 °C |

10.59 °C |

| Relative humidity OUTPUT |

42.43%

|

62.2% |

| Absolute humidity OUTPUT |

5.08g/kg |

5.05g/kg |

| Enthalpy OUTPUT |

29.67 kJ/kg |

23.14 kJ/kg |

| Air velocity |

1.21 m/s |

1.3 m/s |

| Thermal efficiency |

75.26% |

72.4% |

| Humidity efficiency |

60.35% |

58.94% |

| Recuperated power |

0.8kW |

|

| Condensation |

0 kg/h |

|

| Pressure loss |

98.31 Pa |

109.64 Pa

|