WOLF CWL-2-400 - RECUTECH enthalpy exchanger

The most efficient enthalpy exchanger on the market with revolutionary METALPIC fin material – the best choice for Wolf CWL-2-400

This enthalpy exchanger is dimensionally identical to the recuperators in the recuperation unit Wolf CWL-2-400 and may, thanks to its properties, offer better performance than the original enthalpy heat exchanger.

However, it is not an original enthalpy heat exchanger supplied by the unit’s manufacturer.

If we have any doubts about whether you have ordered the correct type of heat exchanger, we will contact you before shipping to clarify everything together.

ATTENTION: Bars on the flat sides are missing. These can be replaced with sealing tape. Sealing tape is included in the delivery.

Anyone can easily apply sealing tape to a heat exchanger.

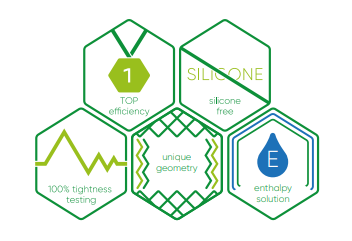

The RFK+ / RFC+ series is a fully enthalpic alternative to the REK+ counterflow aluminum exchangers, which thanks to innovative technology offers not only up to 90% thermal efficiency but also very high humidity efficiency. Thanks to the same dimensions, it is also easy to replace the aluminum and plastic exchanger without further modifications in the heat recovery unit.

- Thermal efficiency up to 90%

- Latent efficiency up to 75%

- High resistance to unbalanced pressure

- High selective permeability

- Unique METALPIC material

- Highest thermal efficiency of all enthalpy products on the market

- High humidity efficiency

- Maximum inlet/outlet pressure difference of 800 Pa outperforms other enthalpy products with polymer-based membrane

- Condensation reduction and significant freezing point reduction

- Permeation of only water vapor through a highly selective permeable membrane

- Guaranteed tightness thanks to 100% production testing

- Use with standard units thanks to standardized dimensions

- Eurovent certification, hygiene certification according to VDI 6022 and reaction to fire classification according to EN 13501-1

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Data sheet

- EUROVENT certification:

- ISO 9001, REACH

- Slat material:

- Metalpic

- Sheathing material:

- Aluminum

- Operating temperature [°C]

- From -20 to +50

- Unit manufacturer

- Wolf

- Country of origin

- Czech Republic

- Product number of the original exchanger

- 2074859

Specific References

- EAN13

- 8592919271364

RECUTECH are equipped with the latest enthalpic membrane METALPIC. They excel in top-class heat and humidity recovery, high resistance to pressure differences, and long service life. They are among the most advanced enthalpic heat exchangers currently available on the market.

ZERN are fully plastic enthalpic heat exchangers, very efficient, with slightly better moisture transfer, but with higher pressure loss.

No, never block the condensate drain.

Even though enthalpic heat exchangers produce only a minimal amount of condensate due to moisture transfer, in severe frost and specific humidity conditions, condensate can still occur. Blocking the drain could cause irreversible damage to your unit.

Since an enthalpic heat exchanger also transfers humidity, it might seem that the risk of mold is higher. In reality, however, all moisture is carried away with the fresh air, so there is no risk of mold growth.

Our recommendation is to never switch off the unit during the winter months, so that moisture is continuously removed. If you still need to shut down the unit, remove the exchanger, rinse it with clean water, dry it thoroughly, and only then reinstall it.

Yes, installation is simple. Just follow the instructions provided with your unit. As with a standard exchanger, it needs to be removed occasionally for cleaning – the process is the same, except that you put the enthalpic exchanger back in instead.

Feel free to contact us with any unit model. We will do our utmost to provide you with a 100% compatible exchanger, regardless of the type of ventilation unit you have.

In any case, the exchangers we supply are identical to the original parts used by the unit manufacturers, and in many cases, our exchangers are even of higher quality. However, we must clearly state that we are not official distributors of spare parts from the unit manufacturers. Transparency is very important to us.

An enthalpic heat exchanger should be used all year round. In winter, it prevents excessive drying of the indoor air, and in summer, it helps maintain comfortable humidity and temperature by reducing heat transfer and returning part of the moisture to the fresh supply air. This increases comfort and saves energy in every season.

No, caring for an enthalpic heat exchanger is no more demanding than for a standard one. Maintenance is described in the user manual and in our video guide. In short: first vacuum the exchanger with a soft brush attachment, then rinse it with clean water (max. 50 °C). Never use compressed air or a pressure washer.

After rinsing, allow all water to drain completely. Remaining moisture can be carefully blown out with a regular hairdryer, but always use cold air only. Once the exchanger is completely dry, place it back into the unit in the same orientation as before removal.

We do not recommend using chemicals for cleaning. Only if disinfection is absolutely necessary may a weak solution of peracetic acid (CH₃CO₃H) at 0.1–0.2% concentration be used, followed by very thorough rinsing with clean water.

Yes, the use of an enthalpic heat exchanger is completely safe. The membrane is designed to allow only water vapor molecules to pass through, while blocking bacteria, odors, and harmful substances. All enthalpic heat exchangers we offer are hygienically tested and certified.

An enthalpic heat exchanger will always help improve indoor humidity, as it transfers part of the moisture from exhaust air back into the fresh supply air. It cannot be guaranteed that ideal levels (typically 40–60%) will be achieved, since the final humidity also depends on other factors – such as household habits, number of occupants, natural moisture sources, and outdoor climate conditions.

However, we can guarantee that humidity will improve, because it is physically impossible for the return of moisture not to contribute to higher values.

The enthalpic plate works the same from both sides, so the orientation of the plate itself does not matter. However, it is essential that after cleaning the exchanger is always reinstalled in the same orientation, ensuring that the channels for fresh air remain for fresh air and the channels for exhaust air remain for exhaust air.

An enthalpic heat exchanger does not generate humidity – it maximizes the transfer of humidity from exhaust air into fresh supply air. If you previously used a standard exchanger, not only the air but also the building structure (walls, ceilings, floors) and porous materials became dry. This means it may take some time for humidity levels to recover, so patience is necessary.

Every enthalpic exchanger we supply is fully functional and improvement is guaranteed. We recommend keeping natural humidity sources (plants, cooking, drying clothes). If you use humidifiers, continue using them until the humidity rises to a comfortable level with the enthalpic exchanger, after which they can be reduced.

Yes. Unlike a standard exchanger, an enthalpic heat exchanger transfers part of the humidity back into the fresh air. This process is gradual, but you can speed it up by adding humidity – either naturally (plants, drying clothes, washing floors) or with humidifiers. Once the humidity has returned to a stable, optimal level, additional humidification can be reduced.

No, an enthalpic heat exchanger does not generate humidity by itself. It only transfers part of the moisture from the exhaust air back into the fresh supply air. If humidity in your home is too high, the cause lies elsewhere (e.g., insufficient ventilation, drying clothes indoors without venting, or residual construction moisture). The enthalpic exchanger helps balance humidity and prevents extreme fluctuations.

An enthalpic heat exchanger works on the principle of counterflow air streams. During ventilation, two separate airflows meet inside – the warm, humid exhaust air from indoors and the cold fresh air from outside. A special membrane transfers both heat and water vapor from the exhaust air to the incoming fresh air without mixing the two streams. This way, fresh air enters the home with a more comfortable temperature and humidity, improving comfort while saving energy.

The sealing tape must be applied around the perimeter of the exchanger, so that when inserted it presses firmly against the unit walls and prevents false air from being drawn in. The surface of the exchanger must be dry and clean before application. Always apply the tape straight, without gaps or folds, to ensure proper sealing.