This enthalpy exchanger is dimensionally identical to the recuperators in the recuperation units Tecalor TCO 2.5, THZ 504-5.5-8.5, 303, 304, 403, 404 and is normally installed in the units.

However, it is not an original spare part supplied and fitted by the manufacturer of the unit, so its use is at the discretion of the user of the recuperation unit.

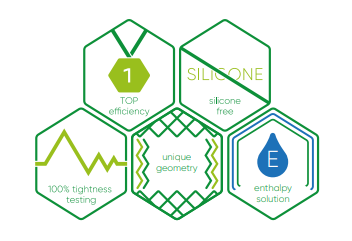

INNOVATIVE SOLUTION FOR YOUR UNIT - Highest temperature efficiency among all enthalpy products on the market

The RFK+ / RFC+ range is a fully enthalpy alternative to the counter flow heat exchangers REK+, offering up to 90 % sensible efficiency and very high latent efficiency thanks to innovative technology. Having identical dimensions, it is easy to interchange the aluminium and enthalpy heat exchanger in an air handling unit, without any adjustments. The RFK+ range offers excellent price-performance ratio.

✓ High humidity efficiency

✓ Sensible efficiency up to 90 %

✓ Latent efficiency up to 75 %

✓ 100% tightness testing

✓ High resistance to unbalanced pressure

✓ High selective permeability

✓ Minimizing condesation

✓ Standard shape and dimensions

✓ Combi solution

✓ Material by METALPIC

✓ Maximum pressure difference supply/exhaust of 800 Pa beats other plastic frame, polymer-based membrane enthalpy products

✓ Eliminates condensation and significantly lowers the freezing point

✓ Permits only water vapour transmission through highly selective permeable membrane

✓ Tightness guaranteed as 100% of the production is tested for internal leakage

✓ Certified by Eurovent , Hygiene VDI 6022 and Classification of reaction to fire EN 13501

What is an enthalpy exchanger?

An enthalpy exchanger recuperates not only heat but, due to the properties and materials used, also humidity.

What makes RECUTECH enthalpy exchangers so unique?

High temperature efficiency – Due to the materials used, no frames are required. As a result, the heat transfer surface is larger and the efficiency of heat transfer increases up to 90%.

Humidity transfer efficiency up to 75%.

Tightness – As you have come to expect, RECUTECH exchangers are tight. This also applies to our enthalpy exchangers.

High resistance to unequal pressure – Due to the robustness of the materials used, our exchangers can resist unequal pressures of up to 800 Pa. They can also be configured so that one fan in the unit draws air in and the other exhausts air.

High selectivity – Our membranes are highly selective. They are highly permeable to water vapour only and no other gases. Verification of selectivity has been tested.

Easy to exchange in existing devices – Due to the same dimensions and similar temperature efficiency parameters, it is easy to exchange the exchanger in your unit with an enthalpy one.

How have we achieved these parameters?

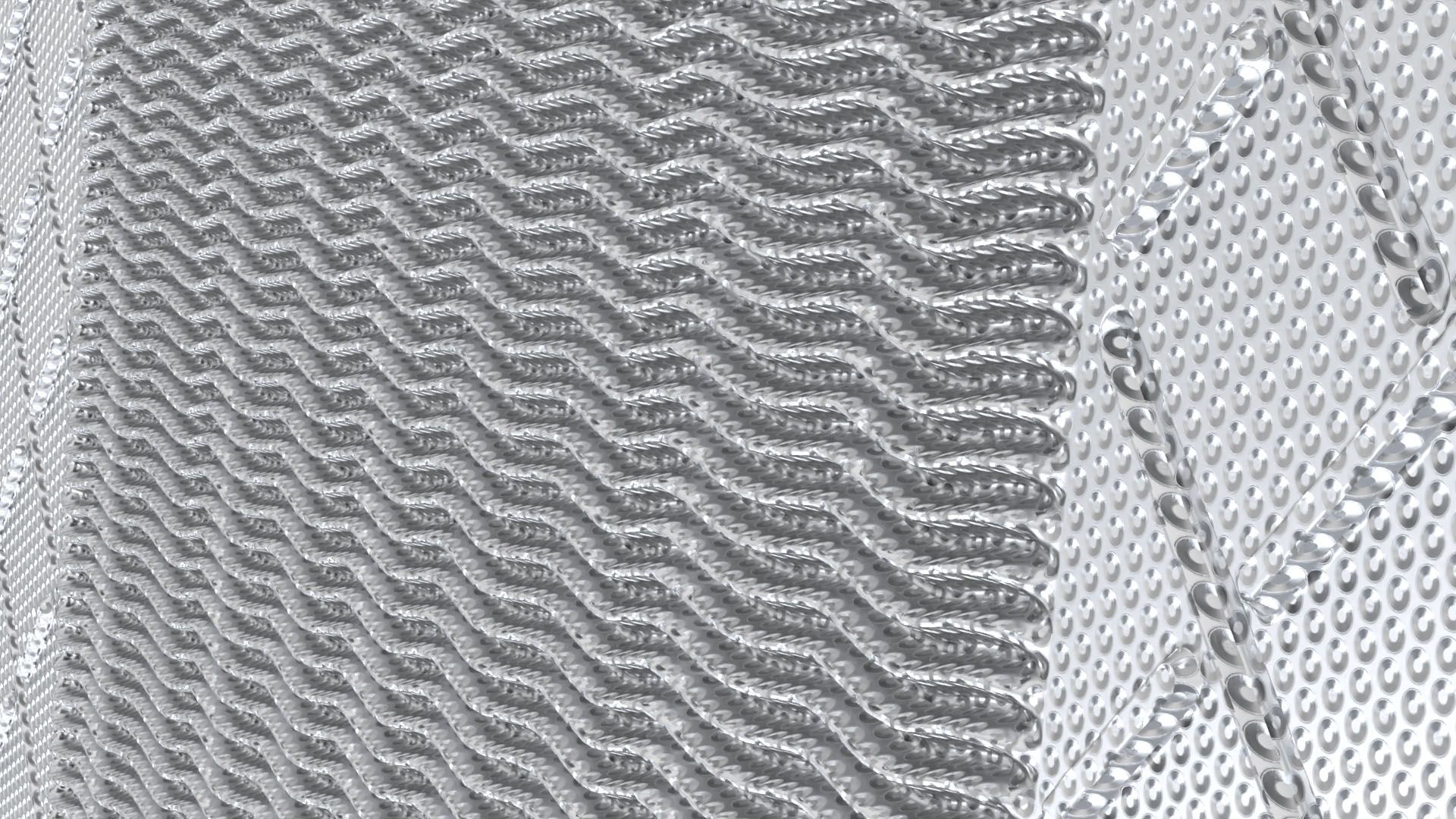

Mainly thanks to the unique Metalpic material which we use in the Recutech enthalpy heat exchangers. This material has been developed by Recutech solely for this purpose. It is a sandwich material where each component has its clearly defined function.

The Metalpic consists of specially treated aluminium mesh with the largest possible open surface. The primary function of the mesh is to support the other component, a thin polymer membrane. Why aluminium? Because this material has excellent heat conductivity and it is easy to recycle.

The second component is the polymer membrane. Its primary function is humidity transfer while keeping the complete plate tight. The membrane is a ion-exchange semi-permeable type.

Thanks to the support of the aluminium mesh, the membrane can be very thin which maximizes the humidity transfer. After the lamination of the membrane to the mesh, the material is processed in the same way as the standard aluminium foil for the REK+ and REC+ heat exchangers. During the process, both components of the sandwich must withstand the same elongation as pure aluminium.

However, thanks to these properties, it is possible to create a plate which is strong enough and has increased heat and humidity transfer surface. The membrane gets thinner during the process as well which means, as mentioned above, increased humidity transfer.

Why use an enthalpy exchanger?

In order to answer this question, it is useful to explain what constitutes the ideal climate for healthy living. The ideal humidity in rooms is 40 – 60% relative humidity and a temperature of 18 – 22°C.

Recuperation with a classic cross-flow or counter-flow exchanger results in interiors being drier, particularly in the winter months because the cold air contains little water and the more humid air inside is exhausted.

The subsequent reduction in relative humidity, which can fall to 20%, can cause the mucous membranes to dry out. As a result, your eyes smart and your body’s resistance to viral and bacterial infections weakens rapidly. In unventilated rooms with low humidity, viruses spread literally at rocket speed.

A secondary effect is that rooms dry out, which can cause wooden floors and furniture to shrink.

Recuperation unit manufacturers are aware of this issue and resolve it, for example, through additional humidification using a so-called “enthalpy flap”, or through the natural diffusion of humidity using a rotating exchanger. However, these solutions have their disadvantages. All components that the outgoing air from the room contains pass through the unit.

Moreover, rotating exchangers are more susceptible to leaks. However, if a rinsing chamber exchanger is used, the “dirty” air is at least partially cleaned, but the efficiency drops and the dimensions of such units increase.

How does an enthalpy counter-flow exchanger work?

In order to also be able to transfer humidity, the material used for the lamella of such exchangers must have this capability. This is enabled by membranes, i.e. special materials that are able to facilitate humidity transfer. This phenomenon is called selective permeability. This means, ideally, permeability to water vapour molecules only. This fact is important to ensure that CO2 and the like are not returned to rooms.

Porous membranes are commonly used, i.e. membranes with micro pores that only allow water molecules to pass through them. The disadvantages of such membranes are that they also allow smaller molecules to pass through them and that the pores slowly become clogged, resulting in their decreasing efficiency over time.

Ion exchange membranes are an alternative. These work on the basis of a water molecule’s ability to “climb” a ladder of ion bonds, whereas other gases and molecules cannot. In practical terms, this means that water vapour molecules can naturally pass from an area of higher humidity to an area of lower humidity, whereas other molecules and gases cannot.

It is in this selectivity that there is a big difference. However, selectivity can be measured by placing a membrane between two spaces, one containing air and the other a different gas (CO2, CO, or NH3). In the space with the air, the gas concentration is measured. If the gas concentration is not measurable in a standard way, then it can also be measured using a gas chromatograph, which determines the content of harmful gas more precisely.

What are other advantages of using an enthalpy exchanger?

In addition to the aforementioned, the freezing point drops. In winter, the cold outside air that enters the exchanger cools the exchanger plates, as a result of which the exhausted air, of which the relative humidity is higher, condenses and gradually freezes. An enthalpy exchanger transfers this humidity to the exhaust air so that when the air reaches the cold parts of the exchanger, it contains much less humidity.

Although the dew point and Mollier’s diagram can help to explain these phenomena, it is sufficient to know that the freezing point for the inlet air drops to approximately -10°C. A conventional exchanger usually struggles at temperatures of -3°C. Due to this, the need to preheat the input air increases, and at an earlier stage, which requires more energy and reduces the total efficiency of the recuperation unit.

Condensation is another disadvantage of classic plate exchanger. Excess humidity must be removed using a condensation tank and the unit needs to be connected to the drains. Moreover, condensing water prevents the air from passing freely and increases the pressure loss.

Highest temperature efficiency among all enthalpy products on the market

Maximum pressure difference supply/exhaust of 800 Pa beats other plastic frame, polymer-based membrane enthalpy products

Eliminates condensation and significantly lowers the freezing point

Permits only water vapour transmission through highly selective permeable membrane

Tightness guaranteed as 100% of the production is tested for internal leakage

Certified by Eurovent , Hygiene VDI 6022 and Classification of reaction to fire EN 13501

ERV core, HRV core, ERV system, HRV system, Ventilation unit filter

![]()

![]()

![]()

![]()

![]()

![]()

![]()